One of the biggest contributors to climate change is right under your feet and transforming it can be a powerful solution for keeping greenhouse gases out of the atmosphere.

Cement production, the connecting element of concrete, was responsible for 7% of total global carbon dioxide emissions in 2018. Concrete is one of the most used resources on Earth, with an estimated production of 26 billion tons. tons annually worldwide. Production is not expected to decline for at least another two decades.

Given the scale of the industry and its greenhouse gas emissions, technologies that can reinvent concrete can have profound impacts on climate change.

As engineers working on infrastructure and construction issues, we are designing the next generation of concrete technology that can reduce the infrastructure’s carbon footprint and increase durability. This includes CO2-infused concrete that blocks greenhouse gas and can be stronger and even foldable.

The sector is ripe for dramatic change, particularly with the Biden government’s promise to invest heavily in infrastructure projects and cut U.S. emissions at the same time. However, to get CO2 to work on concrete on a large scale in a way that dramatically reduces emissions, all of its related emissions must be taken into account.

Rethinking concrete

Concrete is made of aggregate materials – mainly rocks and sand – along with cement and water.

Since about 80% of the concrete’s carbon footprint comes from cement, researchers have been working to find replacement materials.

Industrial by-products, such as iron slag and coal fly ash, are now used frequently to reduce the amount of cement needed. The resulting concrete may have significantly lower emissions because of this change. Alternative binders, such as calcined limestone clay, can also reduce the use of cement. One study found that the use of limestone and calcined clay can reduce emissions by at least 20% and, at the same time, reduce production costs.

In addition to developing mixed cements, researchers and companies are focusing on ways to use the captured CO2 as an ingredient in the concrete itself, blocking it and preventing it from entering the atmosphere. CO2 can be added as aggregates – or injected during mixing. Carbonation curing, also known as CO2 curing, can also be used after molding concrete.

These processes transform CO2 from a gas into a mineral, creating solid carbonates that can also improve the strength of concrete. This means that the structures may need less cement, reducing the amount of related emissions. Companies like CarbonCure and Solidia have developed technologies to use these processes for poured concrete in construction sites and precast concrete, such as concrete blocks and other building materials.

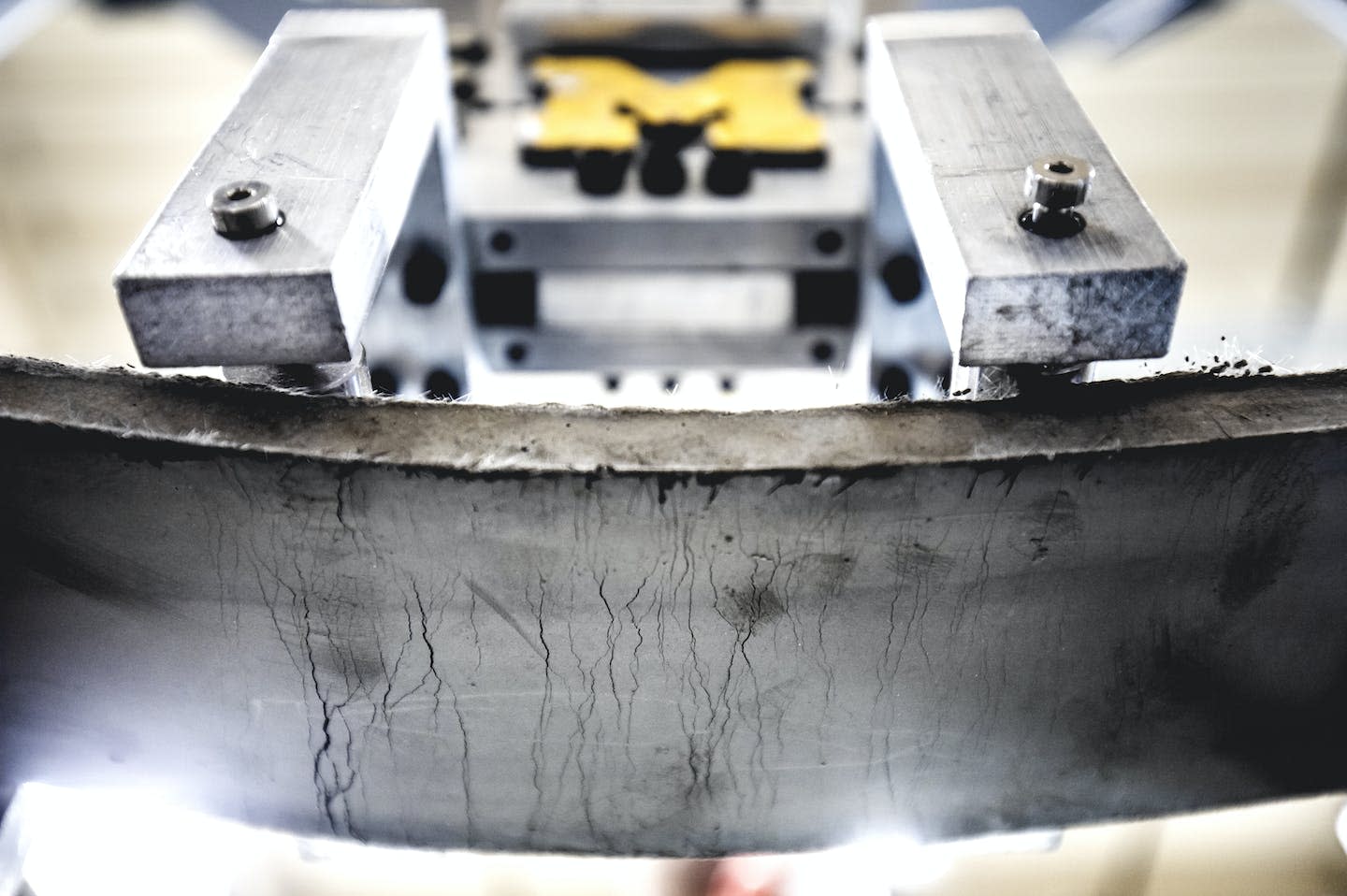

At the University of Michigan, we are working on compounds that produce a foldable concrete material that allows for thinner, less brittle structures that require less steel reinforcement, further reducing related carbon emissions. The material can be designed to maximize the amount of CO2 it can store using smaller particles that readily react with CO2, transforming it into a mineral.

CO2-based foldable concrete can be used for buildings in general, water and energy infrastructure, as well as transportation infrastructure. Foldable concrete was used on the 61-story Kitahama tower in Osaka, Japan, and on the slabs of the road bridge in Ypsilanti, Michigan.

The challenge of life cycle emissions

These cutting-edge technologies may begin to address the carbon footprint of concrete infrastructure, but barriers still exist.

In a study published on February 8, three of us analyzed the life cycle emissions of the CO2 infusion into concrete and found that estimates do not always take into account emissions from CO2 capture, transport and use. With colleagues, we create strategies to ensure that curing carbon has a strong emission benefit.

In general, we recommend developing a standard CO2 cure protocol. Laboratory experiments show that curing with CO2 can improve the strength and durability of concrete, but the results vary according to specific curing procedures and concrete mixes. Research can improve the conditions and time of the steps in the curing process to increase the performance of the concrete. Electricity use – the largest source of emissions during curing – can also be reduced by simplifying the process and possibly using waste heat.

[Deep knowledge, daily. Sign up for The Conversation’s newsletter.]

Advanced concrete mixes, foldable concrete in particular, are already beginning to solve these problems by increasing durability.

Combining infrastructure and climate policy

In 2020, a wide range of companies announced measures to reduce their emissions. However, government investment and procurement policies are still needed to transform the construction industry.

Local governments are taking the first steps. “Low-carbon embedded concrete” rules and designs to reduce the amount of cement in concrete have emerged across the country, including in Marin County, California; Hastings-on-Hudson, New York; and a sidewalk pilot in Portland, Oregon.

In New York and New Jersey, legislators proposed state policies that would provide price discounts in the bidding process for proposals with the lowest concrete emissions. These policies can serve as a plan to reduce carbon emissions from the production of concrete and other construction materials.

Nationally, the collapse of infrastructure administered by the federal government has been an increasing crisis. The Biden government could begin to address these problems, as well as climate change, and create jobs through a strategic infrastructure program.

Transport Secretary Pete Buttigieg recently declared that there were “huge opportunities for job creation, equality and climate achievement when it comes to promoting America’s infrastructure. ” Policies that elevate low-carbon concrete to a national climate solution could follow.

This article was republished from The Conversation, a nonprofit news site dedicated to sharing ideas from academic experts. It was written by: Lucca Henrion, Michigan University; Duo Zhang, Michigan University; Victor C. Li, Michigan Universityand Volker Sick, Michigan University

Read More:

Lucca Henrion works as a researcher at the University of Michigan’s Global CO2 Initiative. He is a volunteer with the Open Air Collective.

Duo Zhang works as an assistant research scientist at the University of Michigan. He conducts research on carbon-scavenging concrete materials.

Victor C. Li receives research funding from the Department of Energy (ARPA-E) and the Aramco Company. He is James R. Rice Distinguished University Professor at the University of Michigan, Ann Arbor. Professor Li runs the Center for Low Carbon Built Environment (CLCBE) at the University of Michigan.

Volker Sick receives funding from the United States Department of Energy and the University of Michigan Global CO2 Initiative.